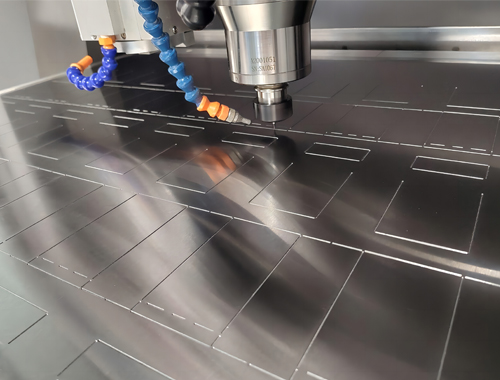

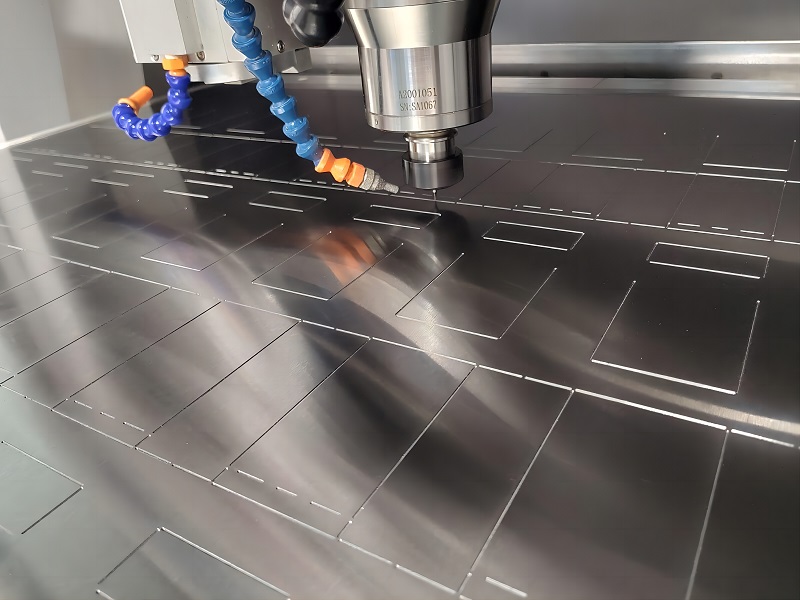

Big size CNC machine for counter/crease plate and embossing / debossing cliches foiling dies

Product Description

ND1200 Series metal CNC machine includes full cover, CCD camera, probe, linear gauge, vacuum table, multi tool changer magazine and so on. The design concept of ND1200 Series metal CNC machine is based on granite bed, beam and guide rail base. It is equipped with high-precision screw guide and high-power/RPM spindle. The whole system is controlled by servo and metal processing of multiple processes through programming completely.

Application Cases

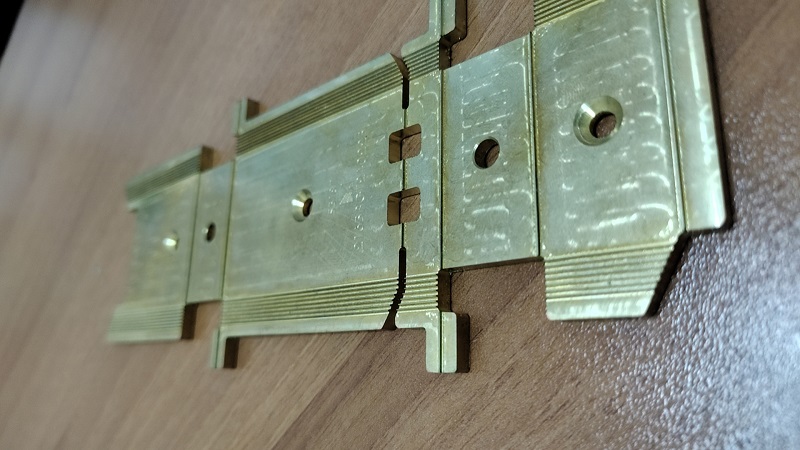

Typical applications include metal(brass&copper, magnesium, aluminum, steel) process. Such as foil stamping dies, embossing dies, metal mould counter plate, crease plate and so on.

Brass&Copper letters dies

3d sculpture

Steel counter plate

Crease plate

TECHNICAL PARAMETERS

Item | Project | Technical Parameters |

Machine accuracy | Positioning accuracy (X/Y/Z axis) | 0.008mm |

Repeated positioning accuracy (X/Y/Z axis) | 0.005mm | |

Straightness accuracy (X/Y/Z axis) | 0.005mm | |

Machine dimension | Spindle spacing | / |

Working distance (X/Y/Z axis) | 1200*800*150mm | |

Working table (X/Y axis) | 1200*800mm | |

Spindle | Max. RPM | 36000rpm |

Power | 6kw | |

Spindle diameter | φ100mm | |

Clamping mode | ISO25-ER16/20/25 | |

Feed | Rapid moving speed (X/Y/Z axis) | 15m/min |

Max.grinding speed (X/Y/Z axis) | 6m/min | |

Machining accuracy | Square dimension accuracy | 0.01mm |

XY plane roundness | 0.015mm | |

Spindle cooling system | Refrigeration flow | ≥3.0mm |

Refrigeration pressure | 3.0-4.0kgf/cm2 | |

Environmental requirement | Working voltage | 380/50v/Hz |

Compressed gas presuure | 0.6Mpa | |

Vacuum pressure | -0.06Mpa | |

Option ATC Magazine | Linear type | Y |

Carrousel type | Y | |

Option full cover | Full cover protection | Y |

Option probe | Probe positioning | Y |

Option linear gauge | Linear gauge | Y |

Option CCD camera | CCD camera | Y |

Machine total power | / | 10kw |

Machine full cover | Dimension | 2790*2120*2250mm |

Weight | 4600kg |

*Machine can select spindle according to user's needs or match with other different functional modules to achieve the user's personalized need.

Our Services

SERVICE PROCESS

A. ND remote training service: support 24 hours -7 days technical support by call or email

B. Support online text&video instruction via Skype, whatsapp, wechat, viber etc

C. Welcome customer come to our factory for check and training before delivery.

D. All of engineers can speak English, then can go to your factory for installation, training and maintain.

GUARANTEE

A. 13 months guarantee of the whole machine.

B. All parts shall be changed free of charge if there is any problem during the warranty period.

We will provide consumable parts and raw material at an agency price.

AFTER SALES SERVICE

A. Contact our after sales engineers by email / skype / whatsapp / wechat or mobile phone, service@nd-cnc.com

Provide your PI number and briefly describe the problem, it’s better to provide pictures or videos to explain.

B. All of engineers can speak English, will reply you within 2 hours(include public holiday and weekend), basic problem will reply solution within 4-8 hours, complexity problem will reply solution within 12 hours.

Packaging & Shipping

Firstly, the cnc center is to be packed with plastic sheet for cleaning and damp proofing.

Secondly, the cnc machine is to be put in the plywood case for safety and clashing.

Thirdly, the plywood case is transported into the container.

Contact

Paul Zheng

Email: paul@nd-cnc.com

Phone/Whatsapp/WeChat/Skype: 0086-151 0691 2735