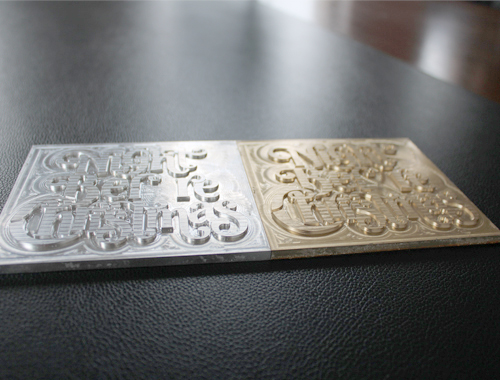

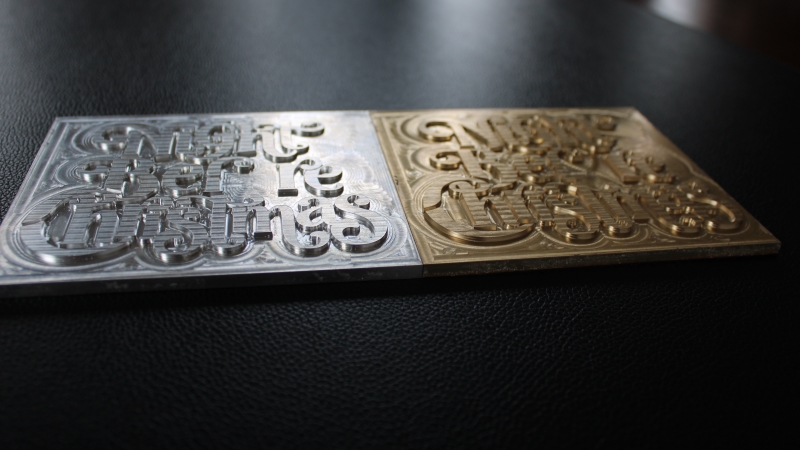

Recently,we made two samples for a Mexico client.

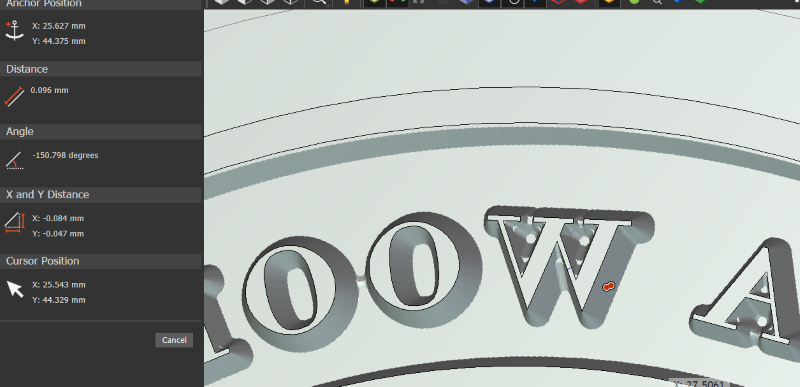

There are brass die and aluminum die,our client sent a ".pdf " format design file,then our CNC MACHINE created the wonderful art for him.

(Digital files,we recommend using PDF sending artworks digitally as this is the most reliable for accurate sizing and font rendering)

The diameter of the samples is 42mm,thickness is 4mm,and the engraving depth is 1mm.Our engineers use 6 tools to make this sample,for surface milling and engraving.

Strive for perfection to make the details of the samples perfect.

If you follow this channel,you may notice the brass die and magnesium die,which are processed by the UK client.

OK,then let us to summarize the difference between dies of different materials briefly.

Brass Dies are the most versatile of all the engraving metals.They are extremely durable,generally used when the highest quality die is required.The number of hot stamping on a copper die can reach more than 50,000. It is widely used in hot stamping of special paper, packaging boxes, greeting cards, films, etc.

Magnesium is the softest material for metal dies.Magnesium Dies are most commonly photo-etched.They are a fast,cost-effective choice for flat foil stamping and some single-level embossing application.Commonly used for hot stamping, embossing, and embossing of general coated paper. The disadvantage is that it is flammable.(Ignition Point,40 ℃)

Aluminium is a silvery-white, lightweight metal. It has a great affinity towards oxygen, forming a protective layer of oxide on the surface when exposed to air.Compared with the other two materials, Aluminum Dies are relatively less used in the hot stamping block industry.

But some of our customers have done well in this field. Our engineers recommend tools specifically suitable for aluminum mold processing to customers based on samples.

If you can patiently read this far, you are really awesome

-END-